Via Wired

-----

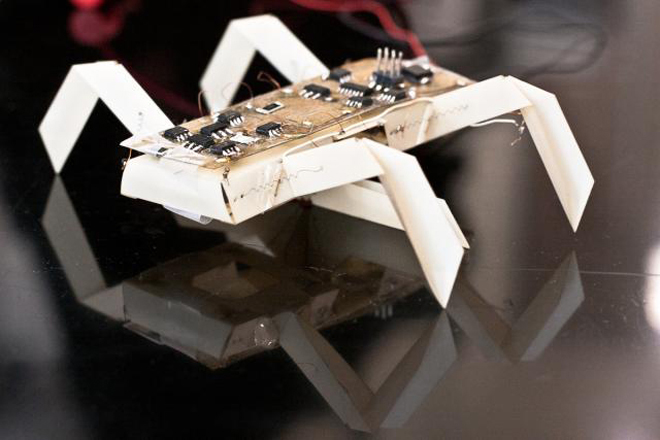

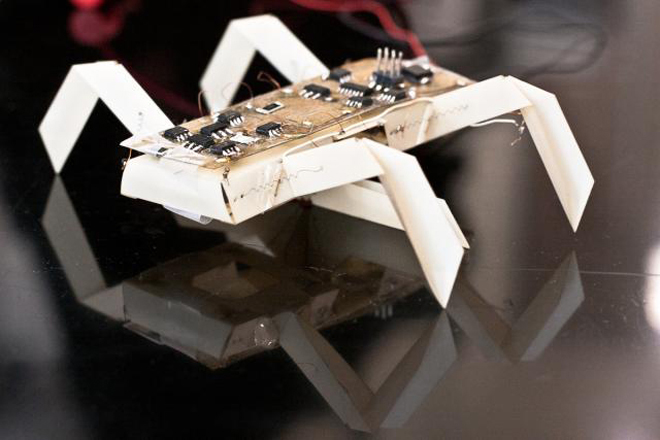

Insect printable robot. Photo: Jason Dorfman, CSAIL/MIT

Printers can make mugs, chocolate and even blood vessels. Now, MIT scientists want to add robo-assistants to the list of printable goodies.

Today, MIT announced a new project, “An Expedition in Computing

Printable Programmable Machines,” that aims to give everyone a chance to

have his or her own robot.

Need help peering into that unreasonably hard-to-reach cabinet, or

wiping down your grimy 15th-story windows? Walk on over to robo-Kinko’s

to print, and within 24 hours you could have a fully programmed working origami bot doing your dirty work.

“No system exists today that will take, as specification, your

functional needs and will produce a machine capable of fulfilling that

need,” MIT robotics engineer and project manager Daniela Rus said.

Unfortunately, the very earliest you’d be able to get your hands on

an almost-instant robot might be 2017. The MIT scientists, along with

collaborators at Harvard University and the University of Pennsylvania,

received a $10 million grant from the National Science Foundation for

the 5-year project. Right now, it’s at very early stages of development.

So far, the team has prototyped two mechanical helpers: an

insect-like robot and a gripper. The 6-legged tick-like printable robot

could be used to check your basement for gas leaks or to play with your

cat, Rus says. And the gripper claw, which picks up objects, might be

helpful in manufacturing, or for people with disabilities, she says.

Printable gripper. Photo: Jason Dorfman, CSAIL/MIT

The two prototypes cost about $100 and took about 70 minutes to

build. The real cost to customers will depend on the robot’s

specifications, its capabilities and the types of parts that are

required for it to work.

The researchers want to create a one-size-fits-most platform to

circumvent the high costs and special hardware and software often

associated with robots. If their project works out, you could go to a

local robo-printer, pick a design from a catalog and customize a robot

according to your needs. Perhaps down the line you could even order-in

your designer bot through an app.

Their approach to machine building could “democratize access to

robots,” Rus said. She envisions producing devices that could detect

toxic chemicals, aid science education in schools, and help around the

house.

Although bringing robots to the masses sounds like a great idea (a

sniffing bot to find lost socks would come in handy), there are still

several potential roadblocks to consider — for example, how users,

especially novice ones, will interact with the printable robots.

“Maybe this novice user will issue a command that will break the

device, and we would like to develop programming environments that have

the capability of catching these bad commands,” Rus said.

As it stands now, a robot would come pre-programmed to perform a set

of tasks, but if a user wanted more advanced actions, he or she could

build up those actions using the bot’s basic capabilities. That advanced

set of commands could be programmed in a computer and beamed wirelessly

to the robot. And as voice parsing systems get better, Rus thinks you

might be able to simply tell your robot to do your bidding.

Durability is another issue. Would these robots be single-use only?

If so, trekking to robo-Kinko’s every time you needed a bot to look

behind the fridge might get old. These are all considerations the

scientists will be grappling with in the lab. They’ll have at least five

years to tease out some solutions.

In the meantime, it’s worth noting that other other groups are also building robots using printers. German engineers printed a white robotic spider last year. The arachnoid carried a camera and equipment to assess chemical spills.

And at Drexel University, paleontologist Kenneth Lacovara and mechanical engineer James Tangorra are trying to create a robotic dinosaur from dino-bone replicas.

The 3-D-printed bones are scaled versions of laser-scanned fossils. By

the end of 2012, Lacovara and Tangorra hope to have a fully mobile

robotic dinosaur, which they want to use to study how dinosaurs, like

large sauropods, moved.

Lancovara thinks the MIT project is an exciting and promising one:

“If it’s a plug-and-play system, then it’s feasible,” he said. But

“obviously, it [also] depends on the complexity of the robot.” He’s seen

complex machines with working gears printed in one piece, he says.

Right now, the MIT researchers are developing an API that would

facilitate custom robot design and writing algorithms for the assembly

process and operations.

If their project works out, we could all have a bot to call our own in a few years. Who said print was dead?