Via Daily Tech

-----

MicroGen

Systems says its chips differ from other vibrational energy-harvesting

devices because they have low manufacturing costs and use nontoxic

material instead of PZT, which contains lead.

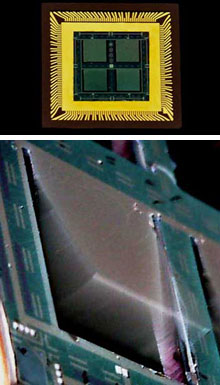

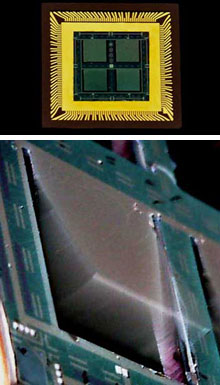

(TOP) Prototype wireless sensor battery with four energy-scavenging chips. (BOTTOM) One chip with a vibrating cantilever (Source: MicroGen Systems )

MicroGen

Systems is in the midst of creating energy-scavenging chips that will convert

environmental vibrations into electricity to power wireless sensors.

The

chip's core consists of an array of small silicon cantilevers that

measure one centimeter squared and are located on a

"postage-stamp-sized" thin film battery. These cantilevers oscillate

when the chip is shook, and at their base is piezoelectric material that produces electrical potential when strained by

vibrations.

The current travels from the piezoelectric array through an electrical device

that converts it to a compatible form for the battery. When jostling the chip

by vibrations of a rotating tire, for example, it can generate 200 microwatts

of power.

Critics such as David Culler, chair of computer science at the University of

California, have said that 200 microwatts may be useful at a small size, but

other harvesting techniques through solar, light, heat, etc. are

more competitive technologies since they can either store the electrical energy

on a battery or use it right away.

But according to Robert Andosca, founder and president of Ithaca, New

York-based MicroGen Systems, his chips differ from other vibrational

energy-harvesting devices because they have low manufacturing costs and use

nontoxic material instead of PZT, which contains lead.

Most piezoelectric materials must be assembled by hand and can be quite large.

But MicroGen's chips can be made inexpensively and small because they are based

on silicon microelectrical mechanical systems. The chips can be made on the

same machines used to make computer chips.

MicroGen Systems hopes to use these energy-harvesting chips to power wireless sensors like those that

monitor tire pressure. The chips could eliminate the need to replace these

batteries.

"It's a pain in the neck to replace those batteries," said Andosca.

MicroGen Systems plans to sell these chips at $1 a piece, depending on the

volume, and hopes to begin selling them in about a year.